Why Deep Cryogenics?

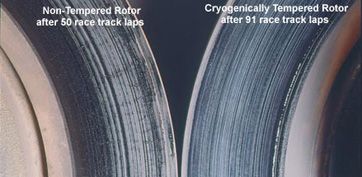

The Frozen Rotors proprietary 60 hour cryogenic process permanently and dramatically improves the usage life and stability of brake rotors to create a distinct advantage in tensile strength, abrasive wear resistance and rotor longevity. By using the cryogenic process to inhibit internal oxidation and increase thermal fatigue resistance, a cryogenically treated rotor can last up to three times as long as untreated rotors. The new technology actually reduces brake pad wear by 40%. Thus, a treated rotor in compared with a non-treated rotor is; free of distortion, has significantly less internal and external oxidation, and posesses reduced thermal fatigue resistance thus causing greater safety and serviceability.

Diversified Cryogenics, Inc. / Frozen Rotors can provide your fleet vehicles with the perfect brake rotor and brake pad combination. We have a variety of choices to fit your exact needs. Whether it’s a police car, pick-up truck, delivery van, or ambulance we have right brakes for your type of usage and driving style

About Frozen Rotors:

Diversified Cryogenics, Inc. (Makers of the Frozen Rotors® brand brake rotors) has been in business since 1996. The Frozen Rotor® brand has been saving police and ambulance fleets money on their maintenance budgets for over 13 years! What is a Frozen Rotor? Well, we start with the highest quality automotive, truck, or SUV brake rotor and then we run it through a 60-hour cryogenic process. Once cryogenically treated, the brake rotor becomes much more resilient to the stresses caused by the constant heating and cooling that a brake rotor is subjected too in its normal operating environment. What you get is a long lasting brake rotor that out performs standard rotors by double the mileage! That means you save money. For more information on our Frozen Rotors® brand go to www.frozenrotors.com.