Imagine a world where cartridges are lighter, cheaper, and more reliable than ever before. Imagine empty brass ejecting cleanly from your gun that is cool to the touch after firing. Imagine picking it up off the range floor with an industrial magnet that can be purchased at any hardware store.

I tested the new ammunition products from Shell Shock Technologies. My concepts about ammunition have been completely shaken, in a very good way.

Wait … what? You said “brass.” Brass is not magnetic.

But, Shell Shock Technology’s “brass” can be retrieved with a magnet. Frankly, I don’t know what to call the product, so let’s stick with brass for now.

What I do know is that they worked flawlessly and did everything the manufacturer claimed they would, and I am now on my fifth reload on the first batch I tested. I have put them through every 9mm I could find, and no product, in my years of testing stuff, has ever left me speechless like this one.

Unless you are a person who reloads fired cartridges for continued practice, most of this is not going to have any impact on you. After all, an agency makes the ammunition decision, and provides it to the officers for duty use. Here is your catch phrase: it’s half the weight of standard brass. Therefore, it shaves ounces off that 17 round magazine.

Traditional brass is usually formed or extruded from a single piece. Brass is a metal alloy used in cartridge manufacture because it is malleable. A loaded cartridge goes into the chamber of a gun. When fired, the brass flows to the dimensions of the chamber. Users who reload ammunition put the brass through a die in order to resize the dimension so it can rechamber.

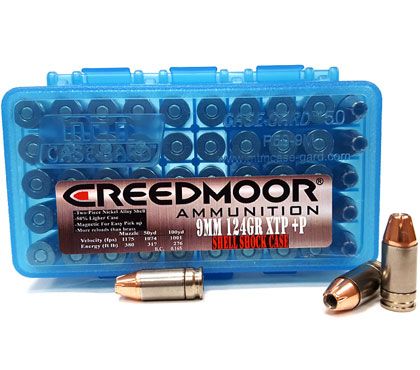

Shell Shock Technology’s brass is a two-piece product. The cylindrical part, closest to the bullet, is a nickel alloy stainless steel. Since regular stainless steel really isn’t magnetic, they have added that property in the formula. The base is nickel-plated aircraft aluminum. They are joined together by a proprietary process. When I heard this, one of the first questions I asked had already been answered. When they are used near seawater, there is no reaction between the two parts.

Steel has a higher tensile strength than brass. When it is fired, it expands momentarily, quickly finding its original dimensions. Before I fired my Shell Shock Technologies cartridges, I thought this through. Stainless steel will chamber easier, because brass has a little more abrasive surface. Because it goes back to its original size after firing, it ejects easier also.

The flash hole in a Shell Shock brass is inherently concentric. It’s slightly larger than a standard flash hole, with a slight taper.

The Shell Shock case can handle quite a bit more chamber pressure than standard brass. For this particular 9 mm, it has been tested as high as 65,000 psi.

There are several law enforcement handguns on the market that do not have fully supported chambers. When standard brass is used, this sometimes can become an issue. When stainless steel products are used in the chamber, it is not an issue at all.

Shell Shock Technologies is a manufacturer supply company. For the most part, they will provide the component for commercial ammunition manufacturing. However, they will also provide their product to end-user customers. For standard brass, the price can be as little as 8 1/2 cents per case. For Shell Shock Technologies, the end user price is about 7 cents per case. When bought in quantity, it can be as cheap as 6 cents per case. No matter how you slice it, the components from Shell Shock Technologies are cheaper. I believe that this will reflect on the end costs of loaded cartridges.

By the way, since the base is aluminum, it can be anodized into any color. This can lead to quick cartridge identification.

Shell Shock Technologies is deliberately aggressive in securing law enforcement RFPs. For agencies, they will offer the lowest price possible in order to secure law enforcement business.

Who makes loaded cartridges using Shell Shock brass?

Anderson Arms/Oak Island Ammunition